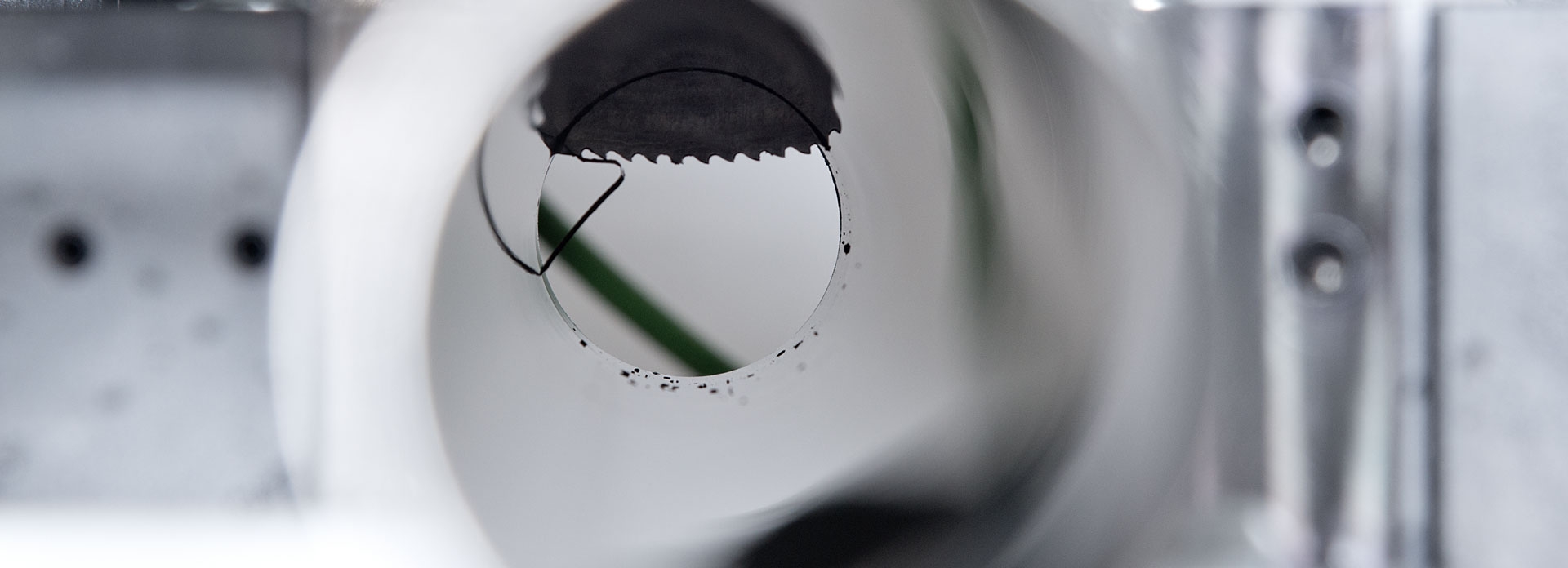

A metal circular saw is used in many industries in order to cut round pipes, square pipes and profiles with the smallest to the mid-sized diameters of 0.6 to 60 mm. Depending upon the material – steel, titanium, chrome-nickel steel, copper, brass, aluminium, silver or gold – the design of our automated sawing machines is adapted to fit those needs. The sawing process can additionally be automated with our many accessories.

Rohbimax precise metal circular saw with short cycle times

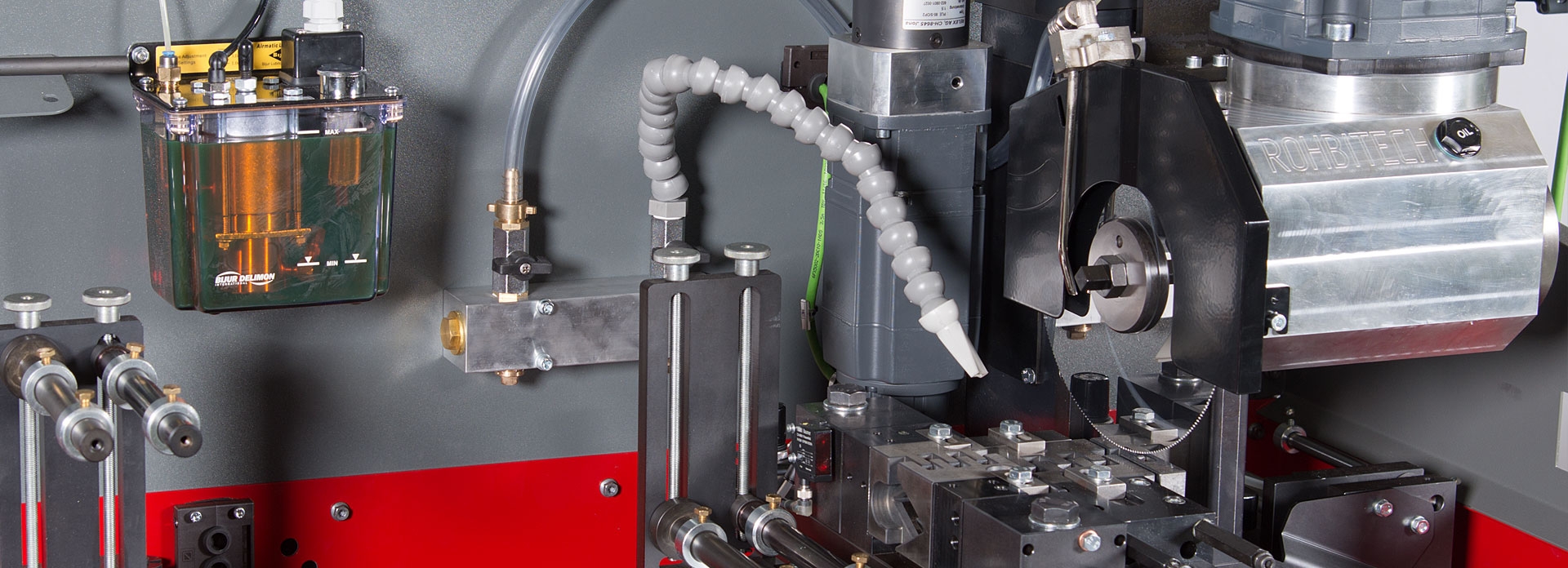

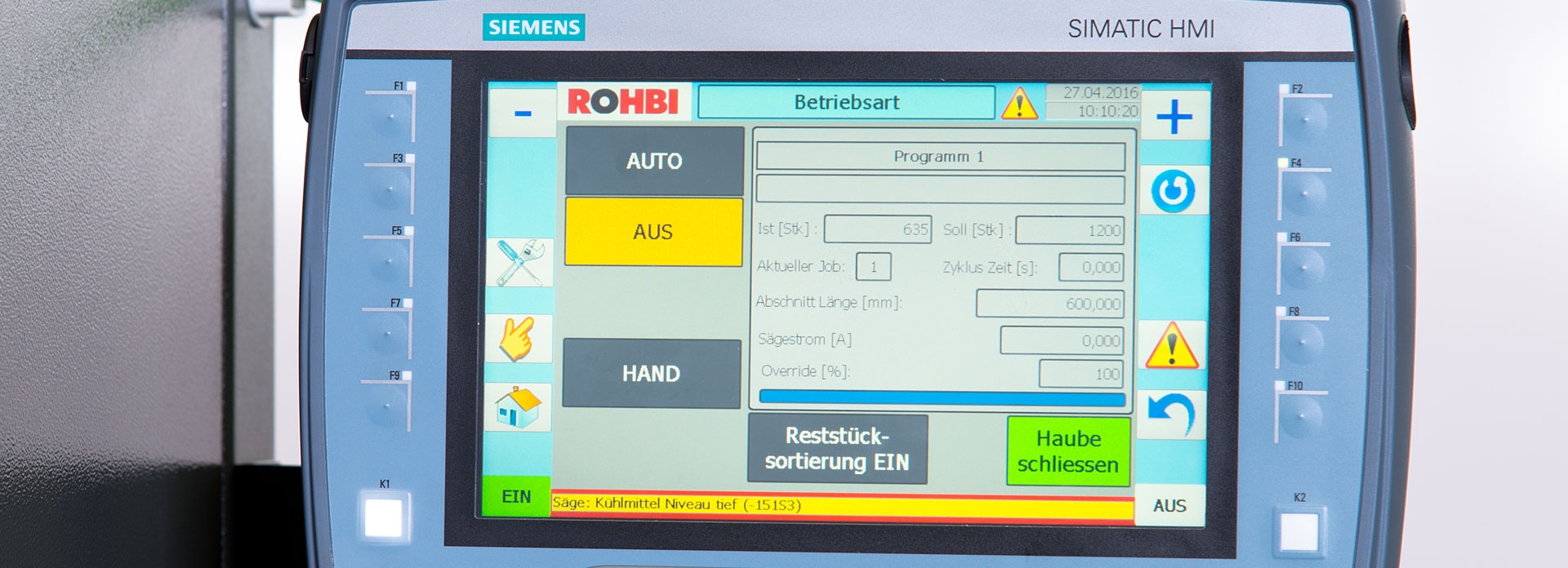

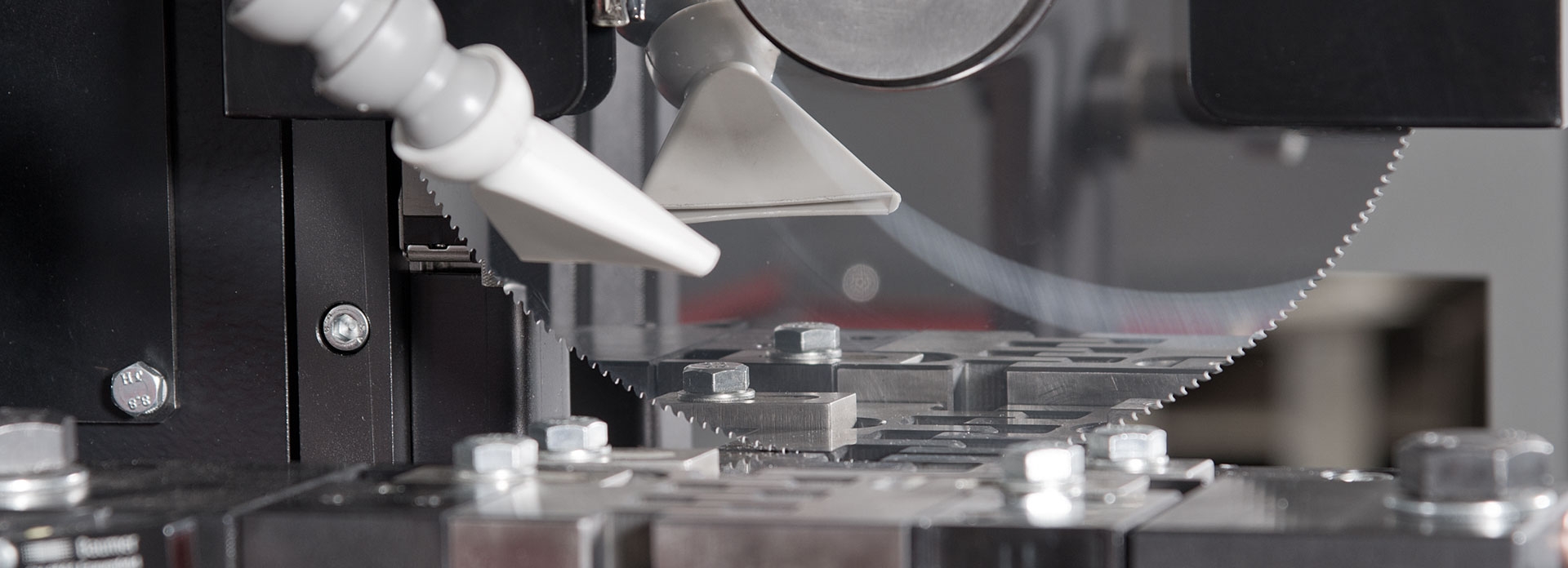

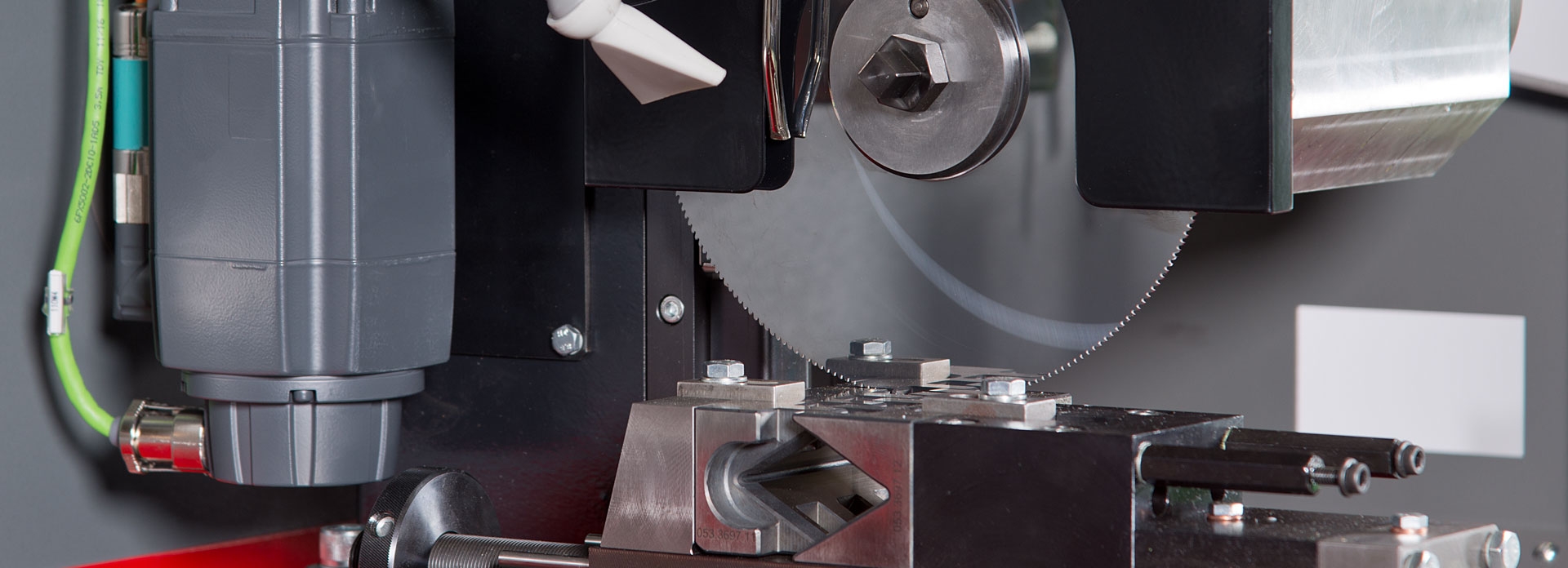

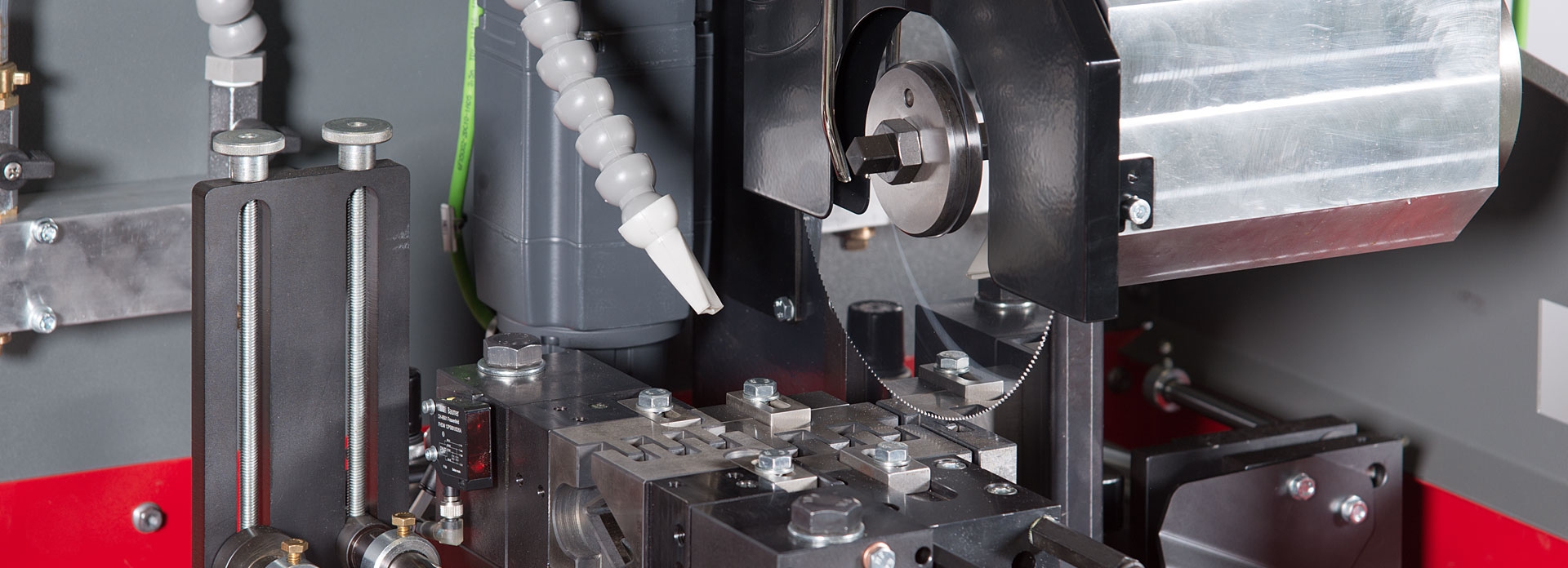

It is decisive that the interplay of components within the entire metal circular saw function optimally in order to provide very precise sawing results. Spindles as well as sawblades must be very high quality – a basic condition so that the metal circular saw and its feeder device cut reliably and exactly. RPMs can be kept high thanks to high-quality sawblades. Rohbimax metal circular saws offer very short cycle times, which results in accelerated production processes. The jaws which affix the material to be sawn, and the clamps which push material as needed, are explicitly designed for the materials and optimally fitted to its dimensions. Due to the automatic stroke in RKA metal circular saws, precision is continuously maintained, and the machine is able to operate independently for several hours.

A metal circular saw is indispensable

Precision circular saws are often used in many industries, including construction, machine tools, vehicle and aircraft construction, electrical equipment, medical devices, office equipment and household appliances. Thanks to low-burr to burr-free material processing, these parts can often be transferred to the next production process without any additional work needing to be performed. Thus, production runs are much slimmer, and great savings can be realised. There are a variety of components for Rohbimax circular saws. One can choose, for example, a roller conveyor, an auto bar feeder, a removal device, shaving removal, a belt filter, a high speed spindle or a rod feeder. These additional elements ensure that the sawing process is automated, improved and rationalised. Of course, Rohbimax AG is available to you after purchase for questions related to operation, repair and overhauls.