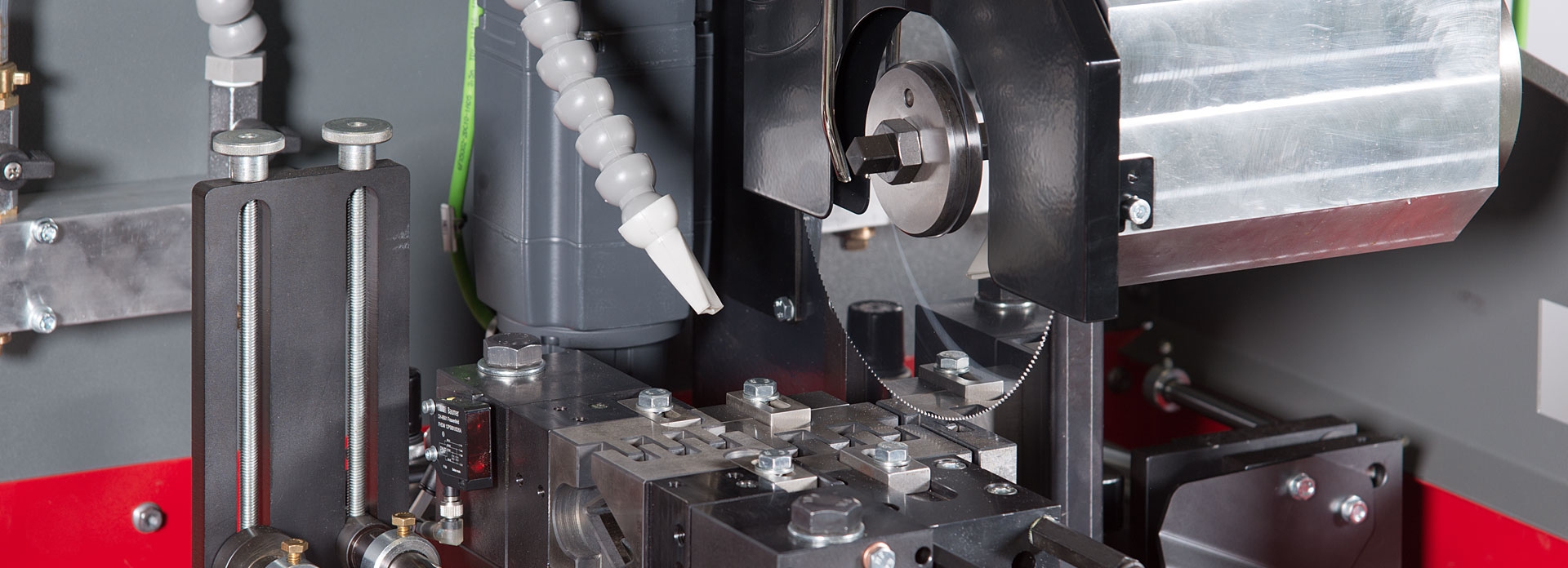

Further processing options provided with a removal device

We provide a smooth-flowing production process

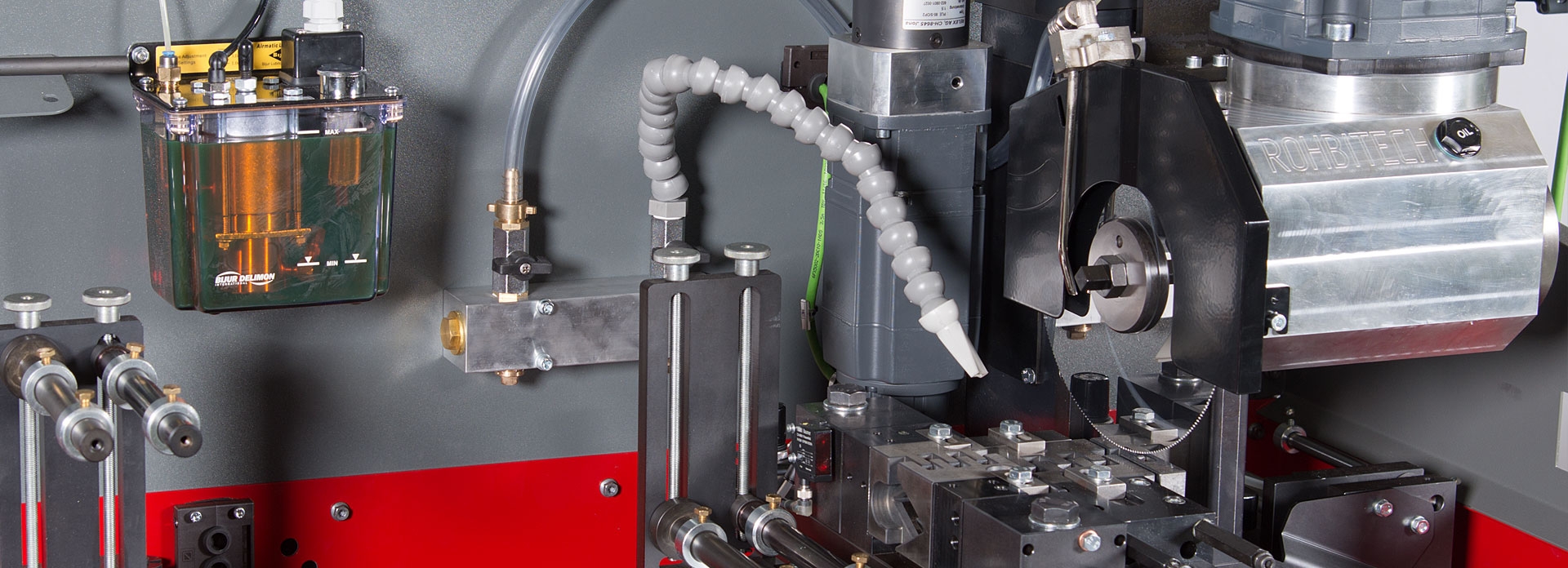

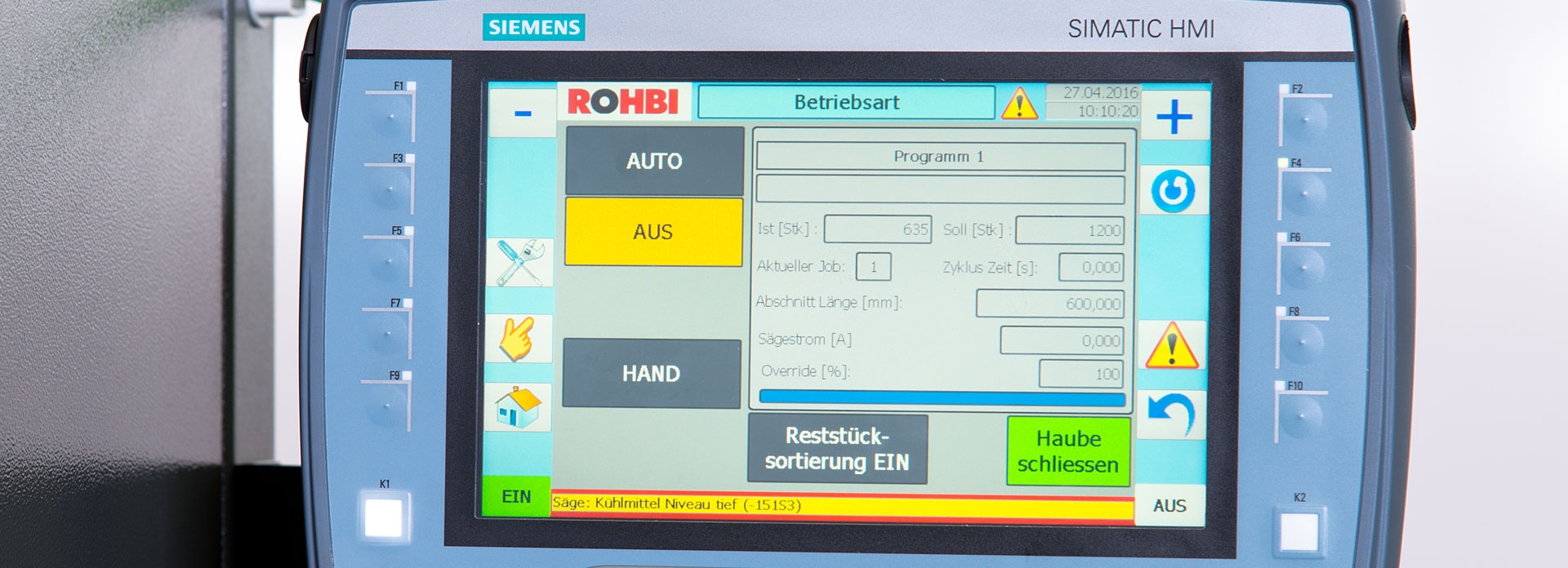

In order to ensure fast and smooth further processing, you have the option through Rohbimax AG to order a removal device in addition to your automated sawing machine. Basically, we offer handling devices with grippers, transport belts or tilting equipment in various versions and dimensions. We would be pleased to advise you about the individual models, depending upon materials, weight and planned production processes, and show you the benefits and drawbacks.

Handling device with a gripper for individual parts

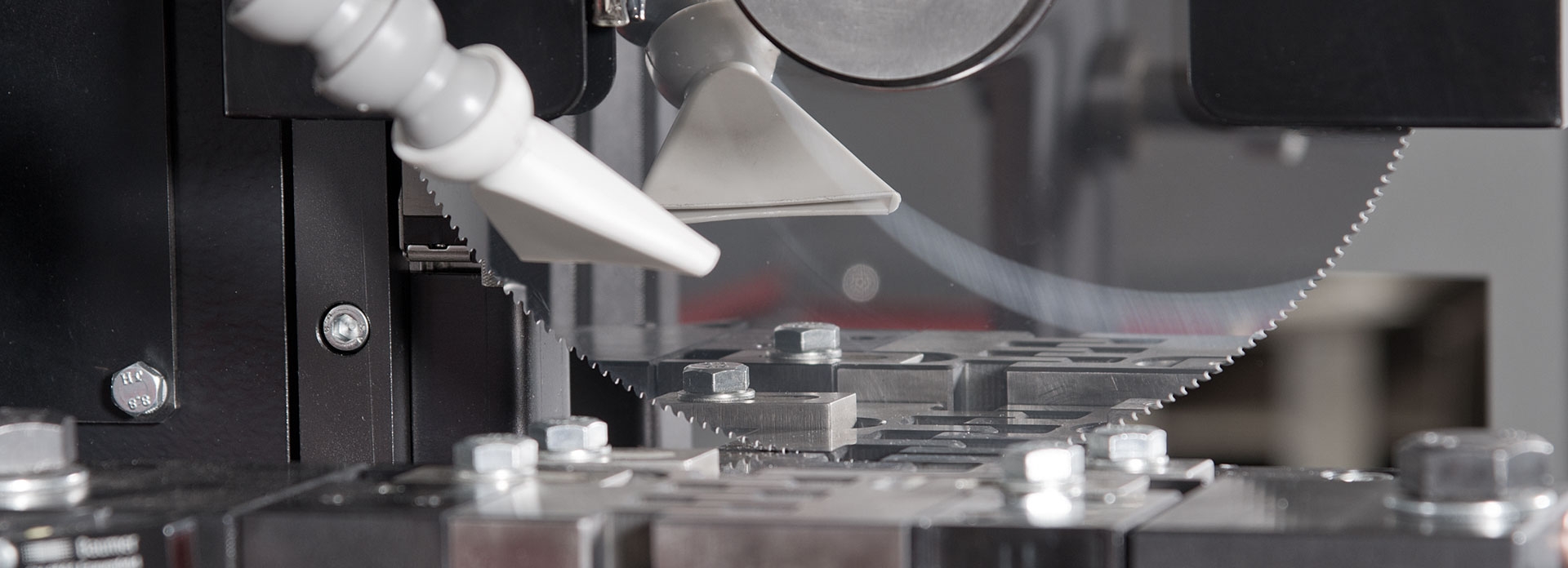

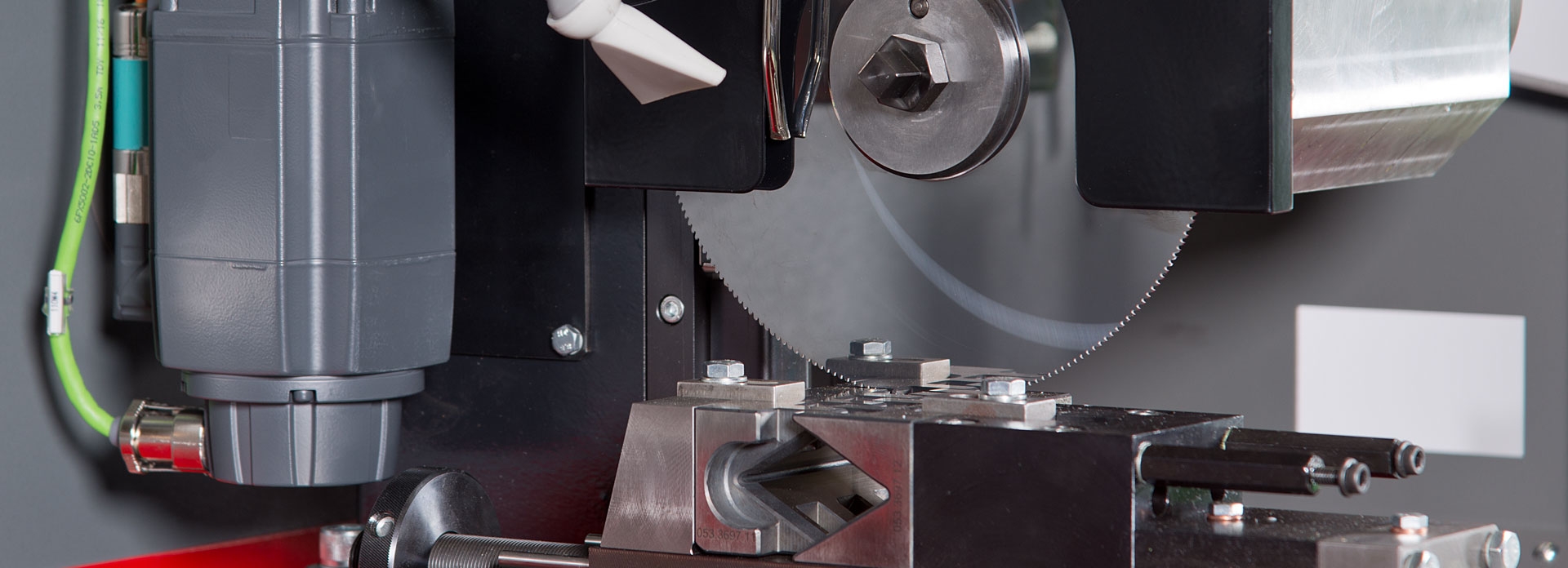

This removal device with a gripper arm takes the product from the machine, and transports it to the desired storage area, or to the next machine. The advantage is that the position and placement of the sawn piece is retained, and that this can be forwarded at any time for further processing at another machine. We don't provide a standard handling device with a gripper. Rather, we adjust the components to meet your needs and requirements. You can order small or large grippers from us, as well as various drive axes which can move forward, backward and return, or from left to right.

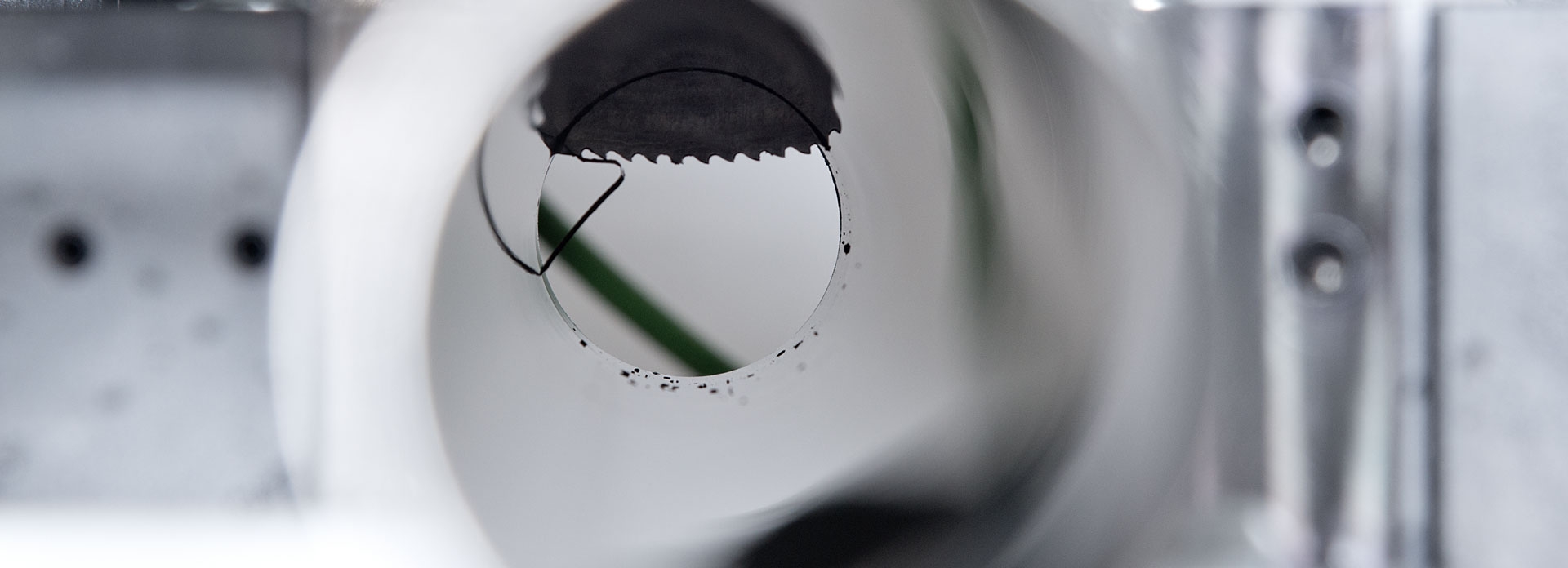

Tilting equipment for efficient sorting of blanks

Tilting equipment can also be used as a removal device: A groove moves to the machine, gathers the sawn parts and lays them gently into the boxes indicated in the program. This removal device can be programmed for each job, so that one can enter, for example, that the tilting equipment can move to the next box after filling with 1000 parts. The groove has removed the component and takes the next one within the turnover time of the machine, between 2 and 30 seconds. This ensures a smooth-flowing production process: The blanks need no longer be sorted by hand. Rather, they can be handled in the next process step. The tilting equipment is especially suited for longer parts. Short sawn parts can already be captured by a slide in the sawing machine or captured in a container. They can be moved to the back by the tilting equipment so that long residual pieces do not affect workflow.